Up until now, Gocator® multi-sensor networking was limited to systems using the same sensor model only (e.g., 4 X high-resolution Gocator 2410s). This approach assumes you want the same field of view and resolution to build a 3D model of a part. However, what if your application requires you to achieve two different aims simultaneously, like scanning a large area and capturing fine surface features?

These “dual purpose” applications cannot be solved using one sensor model alone without making a compromise on resolution. Sensor models that have wide fields of view typically have lower resolution, and sensor models with high resolution typically have much smaller fields of view.

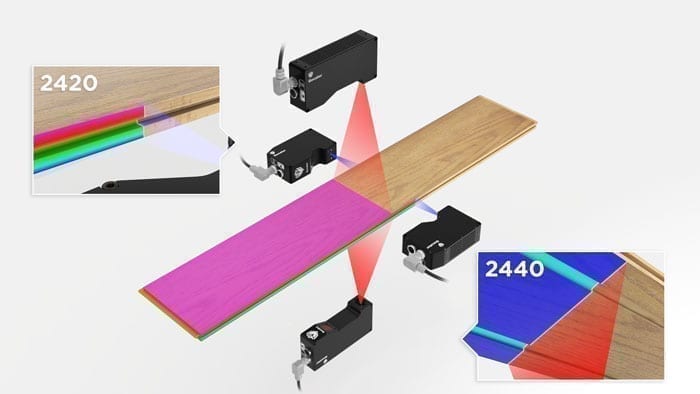

What the engineer really needs to solve the application is the ability to network two different sensor models. This is now possible with mixed model multi-sensor networking using Gocator® smart 3D laser line profilers.

A New Dimension in Multi-Sensor Networking – Mixed Model Systems

Now you can combine different models of Gocator® 3D line profilers from the same series into a single system, taking advantage of the higher resolution of one model and the wider field of view of another. For example, you can set up a sensor system containing one or more high resolution sensors (such as Gocator 2510) with one or more sensors that provide a wider field of view (such as Gocator 2530).

Mixed model networking capability allows you to perform high resolution inspection only on areas where it’s needed (that is, where there are fine features), while simultaneously getting wide overall coverage from other sensors in the network in order to capture the entire object surface.

Now that’s FactorySmart® 3D scanning and inspection!

Watch the video for more details …